The Challenge of Single-Material Excellence

Please no blend!

Our fabrics are crafted exclusively from 100% single-fiber materials. We maintain material purity, avoiding all blends. While this might seem like a minor detail, it's actually a cornerstone of our commitment to quality and sustainability – and a significant challenge in our quest to create superior garments.

Traditionally, fabric blends have been valued for their versatility, offering a range of possibilities in terms of breathability, weight, and durability. By combining different fibers, textile manufacturers have created fabrics with enhanced properties, allowing for adaptability to various climates and uses. These blends have long been popular in fashion and textile design for their ability to balance comfort, functionality, and style.

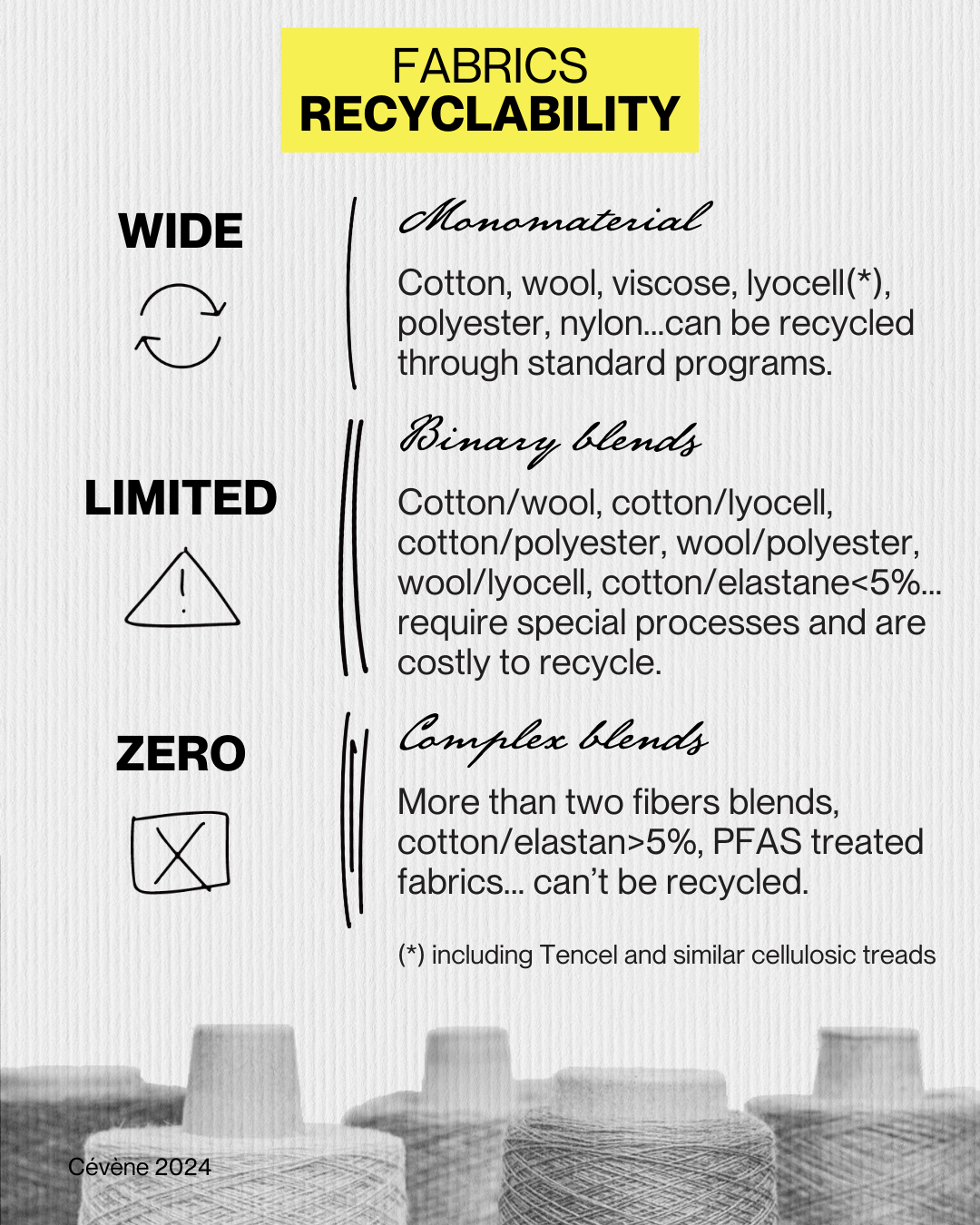

However, this versatility comes at a significant environmental cost. Blended fabrics pose a major challenge in the realm of sustainability. The mixture of different materials makes these textiles extremely difficult, if not impossible, to recycle effectively. When garments made from blended fabrics reach the end of their lifecycle, they often end up in landfills or incinerators, contributing to the growing problem of textile waste.

In response to this challenge, we have pioneered an innovative approach. Through extensive research and development, we have succeeded in matching all the advantages of blended fabrics by working exclusively with monomaterial fibers. Our fabrics deliver the same level of breathability, durability, and adaptability, while remaining fully recyclable. This breakthrough allows us to offer high-performance textiles that meet the demands of modern consumers without compromising on environmental responsibility. By focusing on single-material innovation, we've created a sustainable solution that doesn't sacrifice quality or functionality.

Our Promise

Always at 100%

Achieving these same qualities with 100% monofiber fabrics requires more innovative thinking, harder work in design and production, as well as a higher investment in quality materials.

Still, the extra effort is crucial because of one simple fact: today, it's practically impossible to recycle mixed-fiber fabrics effectively. And when possible, it's often so expensive that it's only done in specialized tech labs, not in real-world recycling facilities.

By choosing our 100% monofiber garments, you're not just getting a high-quality product – you're investing in a fully recyclable future for fashion. Style shouldn't come at the cost of sustainability, and we're proving it's possible to achieve both without compromise. Should a truly efficient and cost-effective method for recycling blended fabrics emerge, we'll re-evaluate our approach. Until then, we remain dedicated to our "pure fabric" philosophy.

Blending problems

The purer the better

Binary blends - fabrics composed of two different fibers - represent the vast majority of blended textiles in use today. Common examples include: cotton-polyester blends (e.g., 65% cotton, 35% polyester, wool-nylon blends (e.g., 80% wool, 20% nylon), cotton-elastane blends (e.g., 95% cotton, 5% elastane).

These blends are popular due to their ability to combine the properties of two different fibers, such as the comfort of natural fibers with the durability or stretch of synthetic ones. However, this blending comes at a cost to recyclability.

- Fiber separation: the main challenge lies in efficiently separating the two fiber types.

- Quality: mechanical recycling processes often struggle to maintain fiber quality during separation.

- Downcycling: many recycled binary blends end up being downcycled rather than truly recycled

Although less common than binary blends, fabrics with more than two fiber types present even greater recycling challenges, with even more complex separation processes making recycling economically unfeasible.

An additional layer of complexity comes with PFAS-treated textiles. These treatments, while providing desirable properties like water and stain resistance, significantly complicate the recycling process and can introduce harmful chemicals into recycled materials. This is one of the reasons why we have carefully selected PFAS-free and biodegradable water-repellent treatments for our fabrics. This choice not only eliminates harmful forever chemicals but also ensures that our products can be efficiently recycled at the end of their lifecycle, supporting a circular economy in the textile industry.